The importance of transformers in electrical systems is not unknown. Transformers are essential for power supply without disruptions. They are also important in adapting to varied voltage levels to suit the various electrical system demands. Given such an important role, transformer failure can lead to significant operational disruptions and safety concerns.

You must have faced power outages at least once in your life. You were irritated with inconveniences in your work and home disruption. One of the reasons for power outrages is transformer failure.

Understanding Transformer Failure

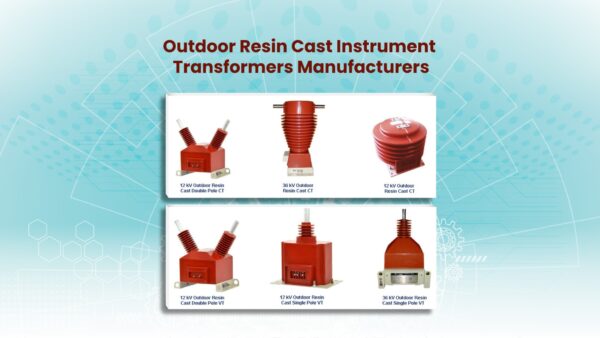

At the end of the day, transformers are machines and they are prone to failure. When signs of failure appear, you must quickly repair or replace the transformer to restore full functionality. The transformer failure has many reasons that we will discuss in this blog from the experts of a Gemini Instratech, a leading Instrument Transformers Manufacturers.

There are two types of transformer failures:

Mechanical Failure

Mechanical transformer failure refers to the physical damage to components of the transformer. These problems may occur for various reasons such as rough treatment of the equipment while shipping and installation, extreme weather, or earthquakes. It is not possible to prevent natural calamity, but mechanical transformer failure due to human errors can be prevented by careful handling.

When you first get your transformer, conduct a sweep frequency response test and compare the results to the specifications to identify issues that may have happened while shipping. Another way to identify mechanical failure is the induction voltage test. Indications of mechanical failure from testing include partial discharge and change in low voltage excitation current.

Electrical Failure

Electrical failure of a transformer happens from damage to the insulation. There can be other reasons as well, such as lightning strikes, excessive voltage, frequent fault currents, and mechanical damage to the insulation.

Without proper insulation, the transformer’s electrical components have a severe chance of overheating. The problems with electrical systems can be analysed with dissolved gas analysis.

Causes Of Transformer Failure

Transformer failures have a range of causes, from natural aging to improper operations. Knowing and understanding these reasons can facilitate failure prevention.

1. Overheating

One of the major causes of transformer failure is overheating caused by exceeding permissible loads as per manufacturer like Gemini Instratech and IEC standards. External factors such as short circuits or cooling system failures also play a role in the overheating of transformers. Neglecting the overheating issues for a long time can lead to insulation breakdown.

2. Improper operations and maintenance of the transformer

Improper operations and maintenance also cause transformer failure. Maintenance is essential for prolonging the life of a transformer. Leaving transformers unattended may leave you unaware of the growing problems before they become major crises. Incorrectly tightened can lead to overheating or short circuits.

In oil-filled devices, oil contamination can result in a damaging rise in internal temperatures. Regular inspection and maintenance can prevent many issues caused by misuse and ensure the device’s longevity.

3. Aging

Like any machine, transformers also degrade with time. The insulating material that separates the transformer’s windings weakens due to natural ageing and constant electrical stress. It increases the risk of faults and breakdowns.

4. Loose Connections

Loose connections are another cause of transformer failure. Connections within the transformer can loosen due to vibration or thermal cycling. Loose connections create high resistance points that generate excessive heat, which is responsible for causing damage to the surrounding components, eventually leading to more serious faults.

5. Environmental Factors

Environmental factors are also responsible for transformer failure as transformers are immune to their surroundings. Extreme temperatures, high humidity, dust and a corrosive environment can accelerate the deterioration of components of transformers.

Preventive Measures

Transformer failure from human errors can be prevented by taking careful measures:

1. Regular Inspection

Regular inspection of any machine is needed to ensure its full functionality. Regularly inspect transformers for any visible damage, such as cracks, scratches, loose connections, corrosion or any other physical deformity.

2. Avoid Overloading

To prevent transformer failure, avoid overloading it. Transformers can take a certain amount of load and going beyond that may cause severe damage. Update your transformers if your load needs have changed to avoid collapse.

3. Timely Maintenance

Time-to-time maintenance is important to keep any device operating in full functionality. Avoiding maintenance to save costs may cost you more in the future. Schedule inspections, oil testing and cleaning are crucial for preventing problems and errors before they cause bigger damage.

4. Environmental Protection

You can not control the environmental changes, but you can protect your device from environmental factors such as moisture, dust, and temperature extremes. This can be done by ensuring proper enclosure sealing, using moisture-absorbing materials like silica gel, and ensuring installation of transformers in climate-controlled places.

5. Age-based replacement

Machines have a finite age. As they age, they become more prone to failure and become less efficient. Implement a strategy for replacing ageing transformers before they reach the end of their operational lifespan.

Conclusion

Transformers are important in preserving the functionality and robustness of electrical systems. Failures of transformers can lead to financial losses, inconvenience, operational disruptions and sometimes, even safety risks. By understanding the causes of failures, you can prevent the major problems that may arise later causing bigger damages.